Water infiltrations, deriving either from accidental events, from possible imprecision, from significant changes occurring on the ground water and so on, can involve the most diverse materials such as concrete, solid masonry of different composition, rocky elements for conferring, etc. The appearance of infiltrations and, above all, their continuation can be a source of considerable economic damage: the unavailability of the affected areas, damage to operating machines, cars, furnishings and so on.

SYNTECH HAG water-reactive polyurethane resins, which catalyze in a few seconds due to their self-expanding properties, hermetically seal the cracks, forever!

Usually the intervention is carried out, except in special cases, without any preparation of the crack and the resins are at perfect ease even in the presence of pressurized water, even very high. It is possible to intervene from both inside and outside the building, without any demolition or excavations. Given the extreme rapidity of the hydro-expansive reaction of SYNTECH HAG resins, it is possible to immediately verify the effectiveness of the intervention.

CLEANING AND SEALING OF INJURIES AND ADJACENT SURFACES

It is always advisable to clean the surfaces affected by the crack, the crawl space or the joint to be waterproofed, especially where the surfaces themselves are invaded by mosses, limestone and generally soiled.

Correct cleaning with a pressure washer, with a steel brush or hard plastic bristles or with a normal cloth, depending on the case, allows, among other things, to highlight the position and course of the lesion and to draw the consequent results. intervention evaluations. The need to pre-seal the crack (for example, with instant-hold products like OSMOCEM QUICK) depends on the width of the crack itself and on the presence of copious water leaks.

ESECUTION OF THE PERFORATIONS

The injection holes can be drilled with different diameters, depths and angles.

In principle, a standard hole must have a diameter between 8 and 12 mm and must be drilled at an angle of about 45°, on either side of the crack or joint (Quincunx).

The distance between each injection hole and the next depends on the width of the crack: generally it varies between 15 and 90 cm, while the distance of the holes, with respect to the slot or the joint, is generally equal to 1/2 of the thickness of the structure and always variable in relation to the size and importance of the structure itself (dams, large retaining walls, rocks, etc.).

The holes must be conveniently clean from dust with an air compressor or manual air extractor.

INSTALLATION OF INJECTORS

Widen the holes drilled of few centimeters, using the drill with a 12 or 13 mm diameter tip.

Install the SYNTECH HAG INIETTORE 120 or 170 flat head screw injectors (based on site requirements), equipped with a non-return seal valve, by hand or by simple percussion with a hammer and tighten them with a 10 or flat wrench, turning clockwise until a complete “expansion” of its rubber part and fixing to the support.

In order to remove from the holes the dust and debris produced by the action of the drill and to ensure the necessary presence of humidity or water, if missing, provide a preliminary injection of water, providing for the subsequent cleaning of the pumping system, with diluent Nitro type, in order to avoid unpleasant clogging of the pumping circuit.

MIX PREPARATION

Mix thoroughly in a bucket, with a suitable wooden or iron rod, the hydrophilic resin component, SYNTECH HAG FLEX or ECO hydro-expansive (based on site requirements) with the preset amount of expansion activator / accelerator (component B ). The recommended dosage of 0.1 kg of component B each 1 kg of component A can be varied (increase in component B in the mixture) in relation to the intensity and severity of the infiltration.

This possible increase allows to regulate the reaction speed of the hydro-expansive resin with water.

The amount of resin and activator to be used, from time to time, is the one that will surely be able to inject depending on the personnel employed and the difficulty of the site, in any case never exceeding 2 – 3 kg.

FIXING THE INJECTOR WITH THE PUMP

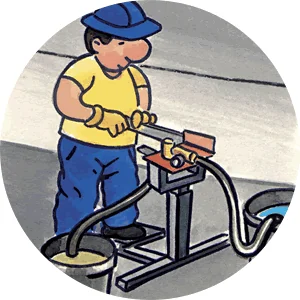

Insert the pump delivery pipe through the specific SYNTECH HAG CONNETTORE interlocking accessory, ensuring the perfect “tightening” of the hose-injector connection before proceeding with the injections.

INJECTION OF HYDRO-EXPANSIVE RESINS

After preparing the resinous mixture and appropriately inserting the delivery pipe of the pump, injections have to be made in the following ways:

- In the case of cracks or vertical joints, injection will start from the first injector installed from the bottom upwards: during the injection it will be possible to notice that the resin will remove the water present in the slot. Continue the injection until the resin arrives, coming out, near the next injector or until the pumping effort becomes excessive.

- Eliminate the air introduced during pumping using the valve of air discharge and, only after ensuring that the air has completely come out, disconnect the pump connection pipe from the injector, and repeat the operation with the next one. The injection pressure is variable depending on the depth of the crack, the structural thickness and the porosity or compactness of the material of the structure. The amount of hydro-expansive resin required will vary, in turn, depending on the characteristics mentioned (depth, thickness, etc.). In standard situations (small cracks, connections between walls and slabs, structural joints, etc.) the consumption of resin can be around 1 kg / linear meter.

REMOVAL OF THE RESIN LEAKAGE AND REMOVAL OF THE INJECTORS

The hydro-expansive resin, escaping from the cracks, joints and crawl spaces at the end of the injections, can develop, especially on dry supports, a remarkable adherence to the surfaces.

Post-injection cleaning can sometimes require the use of a metal scraper to remove residues.

The injectors installed can be removed from their seats by cutting with a flexible disk at the base of the injector and then filling the hole, possibly resulting, with REPAR TIX thixotropic cement mortar.

CLEANING THE PUMP AND ACCESSORIES

Immediately after the injections, it is necessary to clean the equipment that has been in contact with the hydro-expansive resin, proceeding as follows:

- draw with the nitro diluent tube and circulate it into the pump until it comes out of the delivery pipe. This action must be repeated several times until every residue of fluid has completely exited from the pump; then make it spin when dry and then, if necessary, repeat the operation.

- Before placing the cleaned pump, place the specific SYNTECH HAG CLEANER lubricant cleaner in the circuits, so that the pump remains properly lubricated.

Clean the accessories used for the work with the same cleaning agents.

NB: The resulting materials must be disposed of in compliance with the applicable regulations and standards.